Greenhouse Climate Control with Passive Cooling

Eco-friendly cooling for optimal greenhouse growth. ARK’s Passive Cooling System ensures efficiency, water conservation, and uniform temperatures.

Passive Greenhouse Cooling System for Energy-Efficient Climate Control

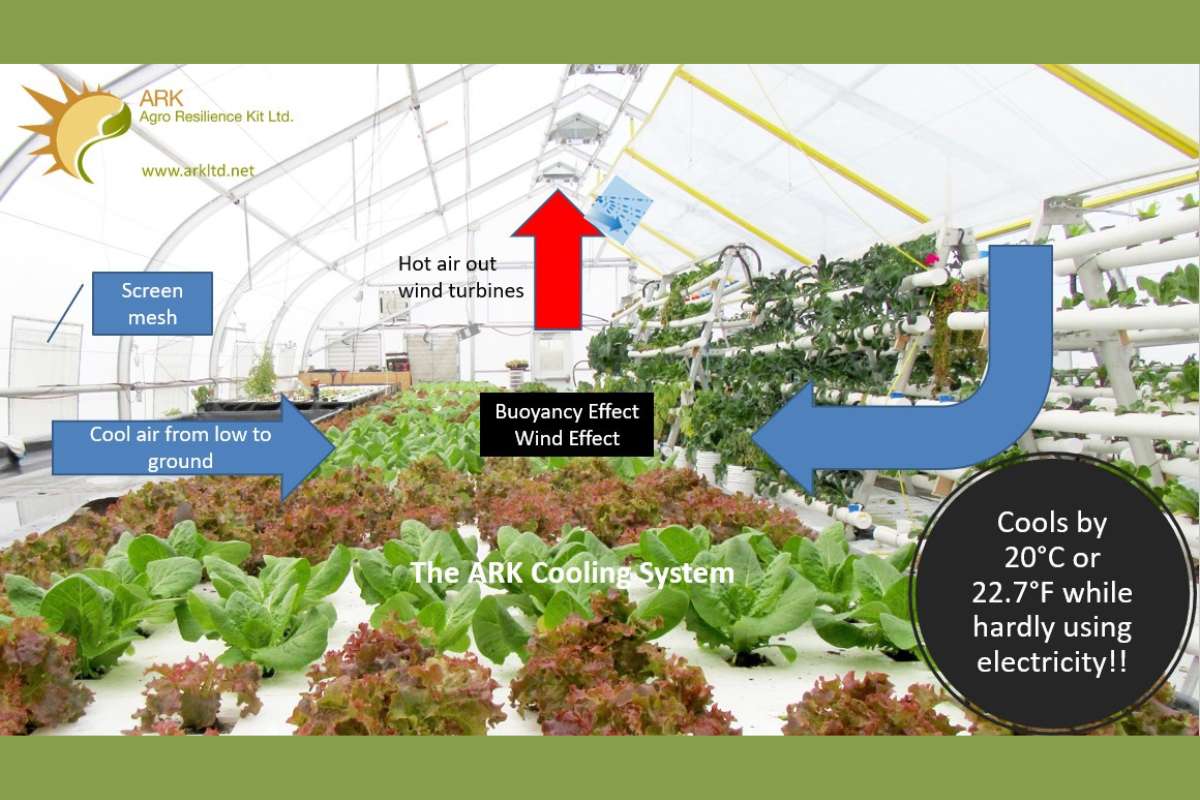

How the ARK Passive Cooling System Works

Unmatched Efficiency and Sustainability

The ARK Passive Cooling System offers significant advantages:

High Energy Efficiency

Water Conservation

Uniform Temperature Control

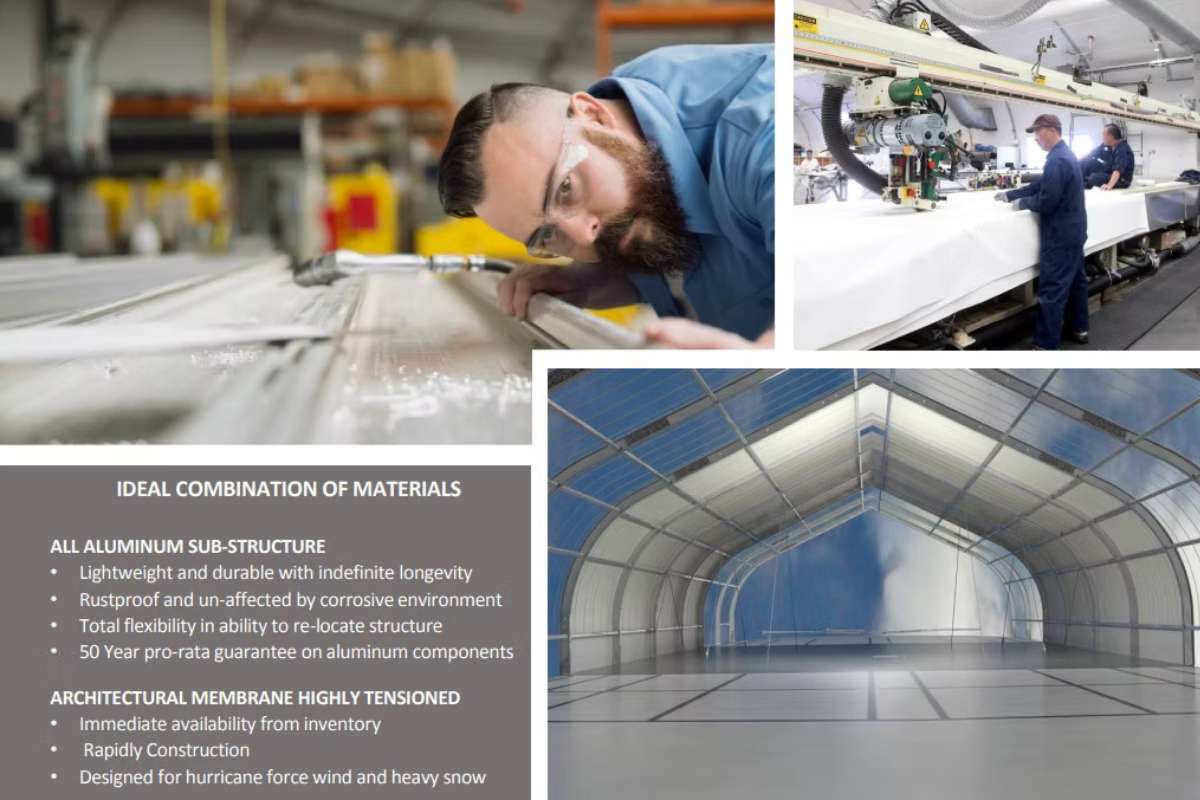

Designed for Durability and Performance

The ARK cooling system integrates seamlessly with Sprung’s high-performance greenhouse membranes.

Built from military-grade aluminum and advanced tensioned fabric, our structures are designed to withstand extreme weather conditions while providing superior thermal control.

This unique combination ensures a long-lasting, reliable solution for greenhouse operators.

The Benefits of Passive Cooling in Greenhouse Environments

Thermal Buoyancy

Wind Effect

Real-World Applications and Proven Results

Get Started with ARK’s Passive Cooling Technology

Experience the benefits of sustainable, energy-efficient cooling. Contact us today to learn how the ARK Passive Cooling System can optimize your greenhouse environment and reduce your operational costs. Contact UsBook A TourAGRO RESILIENCE KIT

Based in Alberta, Agro Resilience Kit (ARK) specializes in sustainable agriculture, providing controlled environment buildings, resilient greenhouses, and water conservation solutions. We support local communities and enhance food security with innovative, climate-adaptive farming systems.